2020.10.23

Toyo Tanso has developed a carbon fiber reinforced carbon composite material (C/C composite) that experiences extremely low oil penetration during oil quenching

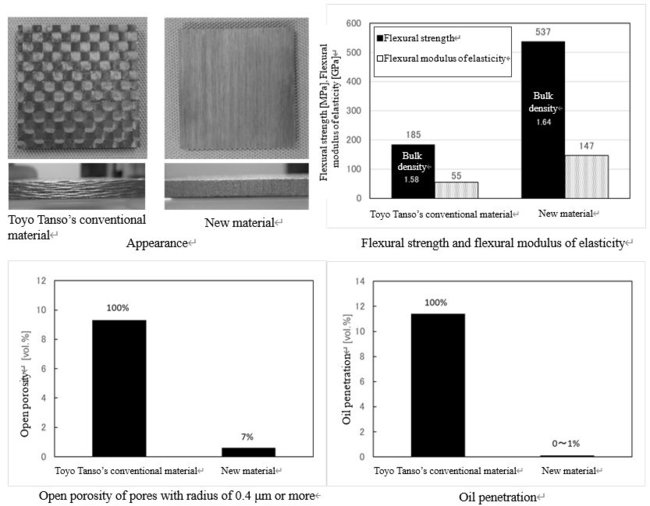

Toyo Tanso Co., Ltd. (Head office: Osaka, President: Naotaka Kondo) has developed a new carbon fiber reinforced carbon composite material (C/C composite) with high mechanical strength that can be used in a wide range of industrial applications, including general industrial furnaces and the environmental/energy fields. The new C/C composite prevents most oil penetration during oil quenching in heat treatment processes, contributing to quality improvement and reduction of environmental burdens. Toyo Tanso will accelerate the rollout process of the material, including sample evaluations, aiming to commercialize it within a year.

Conventional C/C composites are characterized by low weight, high mechanical strength, and high elasticity. Heat treatment jigs made of these C/C composites have seen increasing use for the advantages they offer over metal jigs, particularly that they are easier to handle and more difficult to deform. In heat treatment applications, workpieces (e.g. metal products) are often quenched by being heated to approximately 900°C and then rapidly cooled so that they harden. Typical methods include rapid cooling using gas (gas quenching) or oil (oil quenching). During oil quenching, however, the oil tends to penetrate into the C/C composite, which has a negative impact on the work environment and product quality, leaving stains on the workpieces and soot caused by residual oil.

Toyo Tanso successfully developed this new C/C composite with high mechanical strength, extremely low oil penetration, and low oxidative consumption by improving its conventional molding technology and controlling microscale open pores.

A heat treatment jig made of this C/C composite prevents virtually all oil penetration during oil quenching, and reduces the soot generated during the post-oil-quenching tempering and the following quenching processes. As a result, the work environment and the quality of the workpieces can be expected to improve. Furthermore, heat treatment jigs made of the C/C composite can make a major contribution to cost saving when used with other cooling methods (e.g. gas quenching), since their life cycle is longer thanks to the lower oxidative consumption. Toyo Tanso plans to extend the use of the new material to general industrial applications, as well as heat treatment applications, in the future.

Toyo Tanso will continue to strive to innovate at the cutting-edge of carbons that go beyond carbon, with the aim of supporting advanced industries under their corporate slogan: Inspiration for Innovation.

[Definition of Terms]

C/C composite:A composite material of carbonized plastic that is made by baking and heat-treating carbon fiber reinforced plastic at high temperatures.

Open pore: Microscale empty spaces (pores) contained in an object and exposed to the outside.

Oil penetration: Calculated by immersing a sample in quenching oil that is heated to 100°C, keeping it under reduced pressure for 30 minutes, taking it out, washing off the oil on the surface with a hydrocarbon solvent, air drying and weighing it, and comparing the mass to its pre-test mass.

[Production/Sales Plan]

Production base: Takuma Division (Mitoyo, Kagawa)

Planned production volume: 2 tons/year (at the beginning 1 ton/year)

Planned start of mass production: July 2021 (start of sample distribution: October 2020)

* The data above are measurement examples, not guaranteed values. [Related Link] About carbon products for High Temperature application

[Contact Information] (Product inquiries) Products Inquiry Form