- GlobalNetwork

-

- Global Site

- Americas

-

- United States

France / English | French

Mechanical Carbon

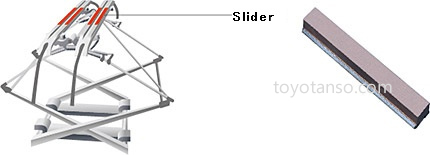

Taking advantage of the self-lubrication and chemical and heat resistance features of carbon, mechanical carbon is used for sliding parts in high temperature environments where metals cannot be used as well as for submersion in chemicals and in fields where lubricated parts cannot be used. Already, our KC, TUG and IG Series are widely used and highly evaluated in a broad range of industries. Our copper-impregnated carbon materials for a pantograph slider are extending the life of wiring.

Feature

Carbon sliding materials have excellent self-lubricating properties, heat resistance and chemical resistance. This means they can be used in high-temperature atmospheres where ordinary metal sliding materials cannot, and in fields where fluids and lubricants are inappropriate. Toyo Tanso’s IG, KC and TUG product series bring together the technical and development capabilities in the fields of sliding materials that have been cultivated over many years, to meet the various demands of our customers.

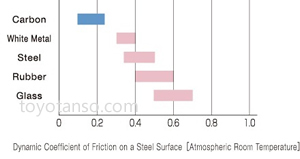

- Excellent Self-Lubrication

- Carbon has self-lubricating properties due to its layered crystal structure, making it appropriate for use in high temperature atmospheres and in applications where fluids and lubricants are avoided. In particular, its coefficient of friction in an unlubricated condition is low compared with other materials, making adhesion difficult to occur.

- Excellent Thermal Durability

- There are virtually no changes in the mechanical strength and slide properties due to heat.

- Excellent Chemical Resistance

- With the exception of inorganic chemicals (strong oxidizers), carbon has excellent chemical resistance.

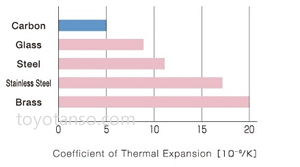

- Thermal Shock Resistance

- The coefficient of thermal expansion is lower than metal materials, and it has good thermal conductivity. This means that the material hardly ever cracks, even during rapid temperature changes.

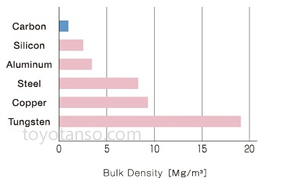

- Supports Lightweight Designs

- The bulk density is low compared to metal materials, which support lightweight machinery designs and a reduction in friction noise.

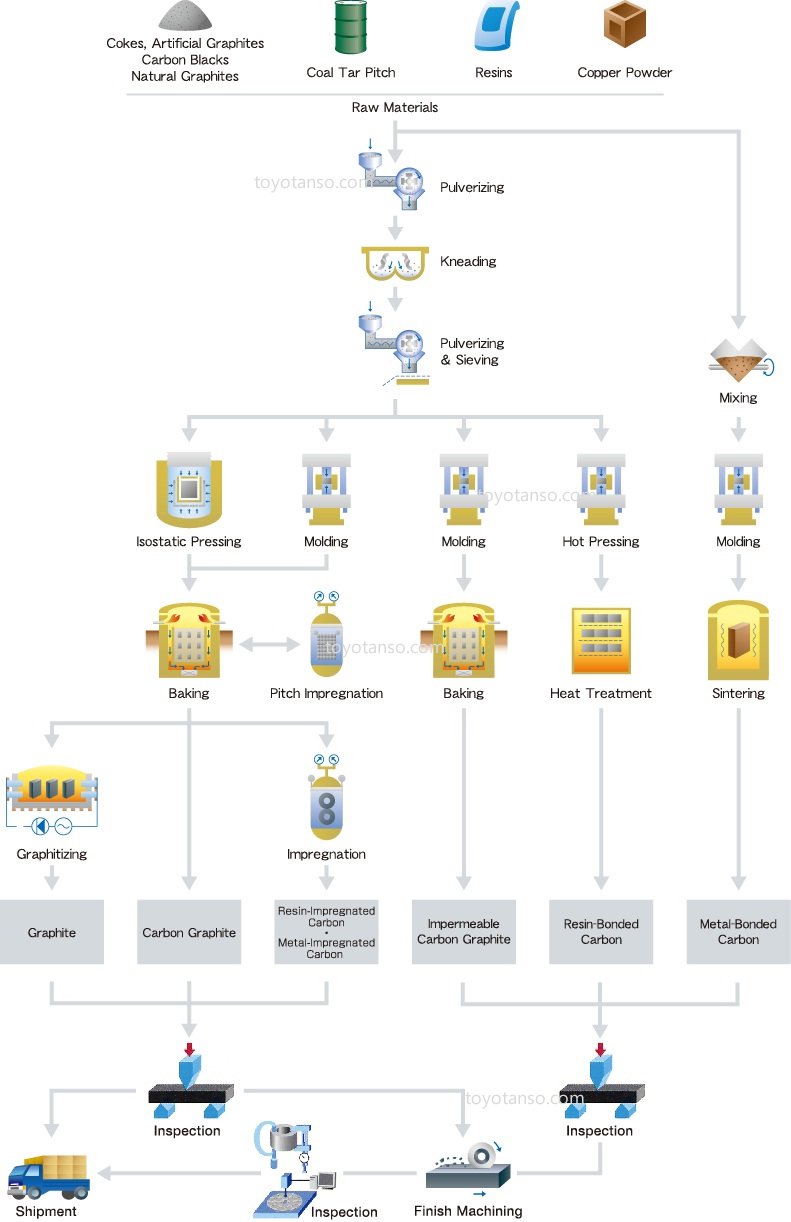

Manufacturing Process

Application

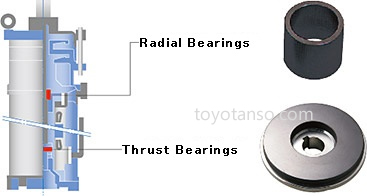

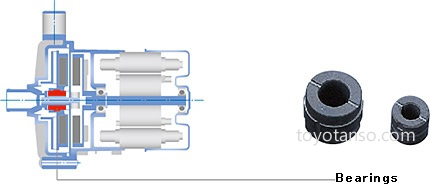

Bearings

Deep well underwater motor pumps

Pumps for oil refining and petrochemical processes

Pumps for power station processes

Pumps for general industries

Chemical pumps

Marine pumps

Flowmeter pumps

Pumps for oil refining and petrochemical processes

Pumps for power station processes

Pumps for general industries

Chemical pumps

Marine pumps

Flowmeter pumps

Household hot water circulation pumps

Vending machine circulation pumps

Dishwashers

Plywood dryer

Vending machine circulation pumps

Dishwashers

Plywood dryer

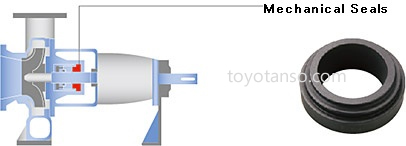

Seal rings

Pumps for oil refining and petrochemical processes

Pumps for power station processes

Pumps for general industries

Chemical pumps

Agitator

Pumps for power station processes

Pumps for general industries

Chemical pumps

Agitator

Marine pumps

Automobile water pumps

Household hot water circulation pumps

Refrigerator compressors

Automobile water pumps

Household hot water circulation pumps

Refrigerator compressors

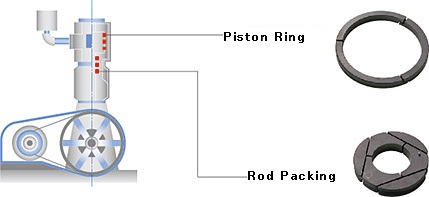

Packing

Reciprocal compressors

Screw compressors

Steam turbines

hydroelectric power generators

Screw compressors

Steam turbines

hydroelectric power generators

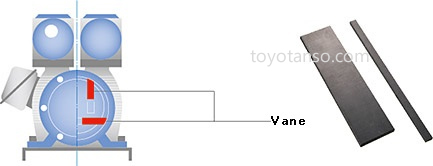

Vanes

Various vacuum pumps

Air blowers

Flow meters

Oscillating compressors

Jet heaters

Air blowers

Flow meters

Oscillating compressors

Jet heaters

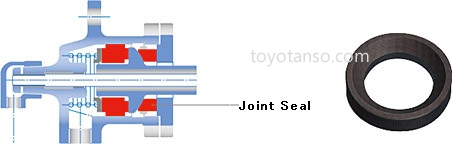

Joint Seals

Papermaking dryers

Drum dryers

Mixing mills

Printers

Drum dryers

Mixing mills

Printers

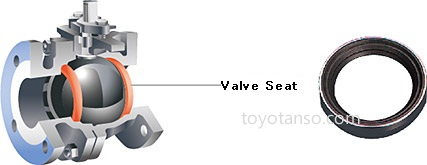

Valve Seats

Ball valves

Pantograph Sliders

JR regular lines

Japanese private railways

Japanese private railways