- GlobalNetwork

-

- Global Site

- Americas

-

- United States

France / English | French

Industrial Furnaces

Heat treatment is applied to industrial products to improve the properties of metal products, sinter ceramics and metals, and for various other purposes.

The various heat treatment furnaces used in these processes frequently make use of carbon materials that offer excellent heat resistance because they can withstand high temperature environments of 500°C or higher (*1).

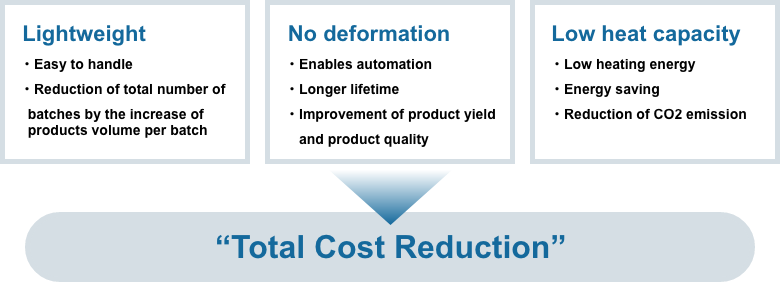

In addition, to improve the efficiency of the treatment, jigs made of lightweight and high-strength C/C composite have various advantages over their metal counterparts.

(*1: In the case of inert atmosphere)

The various heat treatment furnaces used in these processes frequently make use of carbon materials that offer excellent heat resistance because they can withstand high temperature environments of 500°C or higher (*1).

In addition, to improve the efficiency of the treatment, jigs made of lightweight and high-strength C/C composite have various advantages over their metal counterparts.

(*1: In the case of inert atmosphere)

About C/C composites for industrial furnaces

Advantages of C/C composite jigs

Metal jigs deform with repeated use, but C/C composite jigs offer excellent high temperature strength and do not deform, allowing automation using robots, etc. for workpiece installation and jig transfer.

In addition, the light weight of the C/C composite jig improves handling and packing efficiency.

Condition of metal and C/C composite trays after about 1 year of use

Metal tray

(with deformation)

(with deformation)

C/C composite tray

(no deformation)

(no deformation)

Super heat-resistant materials

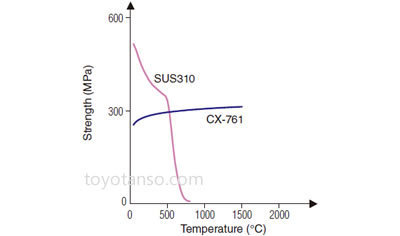

Compared to metal materials, C/C composites have higher strength at high temperatures and can be used at ultra-high temperatures of 2000°C or higher in an inert atmosphere.

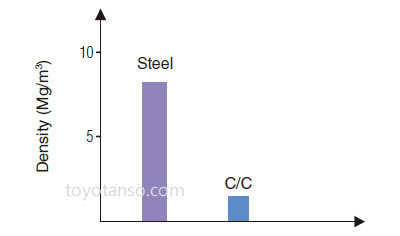

Light weight

C/C composites are light weight and easy to handle. Compared to metallic materials, they have lower density and can be made lighter.

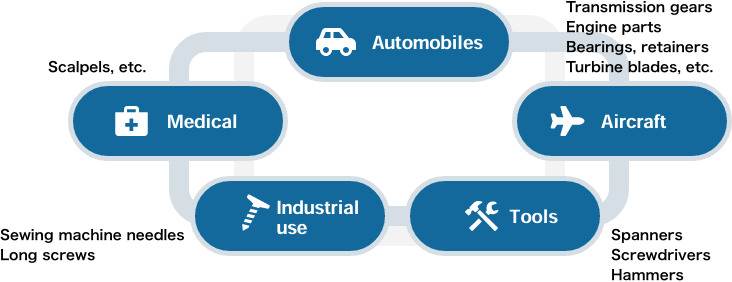

Example of use: Heat treatment process of metal parts that require toughness

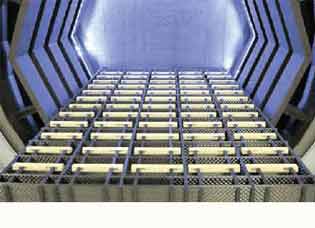

C/C composite jig product examples

We can propose appropriate materials and design to suit each customer's usage conditions and requirements.

Carbon materials are often used for industrial furnace components (heaters, insulation, insulation protection, structural components, shelves, baskets, etc.).

We have a wide range of carbon products such as isotropic graphite, C/C composite, graphite sheet (PERMA-FOILR), etc., that can be selected to suit each customer's usage conditions and requirements, and can propose appropriate materials and design for each jig.

We have a wide range of carbon products such as isotropic graphite, C/C composite, graphite sheet (PERMA-FOILR), etc., that can be selected to suit each customer's usage conditions and requirements, and can propose appropriate materials and design for each jig.

| Products name | Overview | Product Processing Examples |

|---|---|---|

| Base tray (grid) |

- Customizable designs made to order for maximum load. |  |

| Basket | - Customizable designs to fit your workpiece size. - Productivity improvement by stacking baskets. |

|

| Roller hearth | -High heat resistance and no thermal deformation help make conveying stable. |  |

| C/C mesh | - Mesh structure provides high gas permeability. - Combination use with grid & basket is possible. |

|

| C/C corrugated plate | -Stabilize work, even cylindrical products can be used. -Can be used in combination with grid or basket. |

|

| C/C spring | - Maintains stable pressing force even at high temperatures - Minimal decrease in spring constant after repeated use at high temperatures |

|

Feature

- Excellent thermal resistance

- Excellent chemical resistance

- Excellent thermal shock resistance

- Induction heating and direct electrification possible

- Good workability Lightweight, reduction of energy loss (C/C composite)