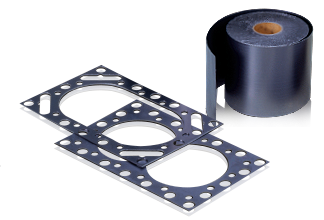

PERMA-FOIL® is a flexible graphite sheet made from specially processed natural graphite without use of a binder. Special processing developed by us gives it a flexibility and compression recovery not found with conventional graphite products. These qualities ensure a snug fit with contacting parts, therefore it is widely used as a seal, to note automotive gaskets and packing.