- GlobalNetwork

-

- Global Site

- Americas

-

- United States

C/C composite

Feature

Feature of Special Graphite Products

- High mechanical strength, high elasticity, and high toughness

-

C/C composites have higher strength, flexural resistance, and resistance to cracking and chipping, compared to isotropic graphite materials. C/C composites can be used with assurance, as the fractures do not propagate rapidly in them.

C/C composites have higher strength, flexural resistance, and resistance to cracking and chipping, compared to isotropic graphite materials. C/C composites can be used with assurance, as the fractures do not propagate rapidly in them.

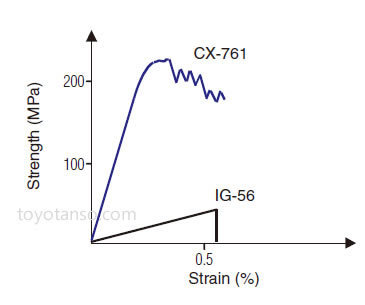

High Strength: The strength is about 3 to 4 times that of isotropic graphite.

High Elasticity: The modulus of elasticity is about 5 times that of isotropic graphite.

High Toughness: No rapid progression of breakdowns.

Note : C/C composite is an anisotropic material and requires careful orientation. - Ultra heat resistance

-

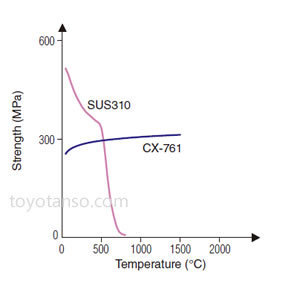

C/C composites have higher strength at high temperatures compared to metallic materials. They can be used even at ultra-high temperatures of 2000℃ or higher in inert atmospheres.

C/C composites have higher strength at high temperatures compared to metallic materials. They can be used even at ultra-high temperatures of 2000℃ or higher in inert atmospheres. - Light- weight and easy to handle

-

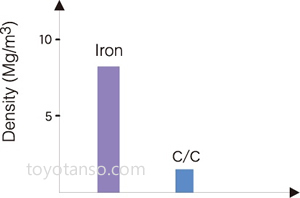

C/C composites have low density compared to metallic materials and therefore, make light weight designing possible.

C/C composites have low density compared to metallic materials and therefore, make light weight designing possible. - High thermal conductivity

-

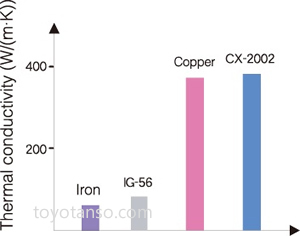

A thermal conductivity higher than copper has been achieved (in CX-2002) through the use of carbon structure control technology, which involves our superior chemical vapor infiltration (CVI) treatment.

A thermal conductivity higher than copper has been achieved (in CX-2002) through the use of carbon structure control technology, which involves our superior chemical vapor infiltration (CVI) treatment.

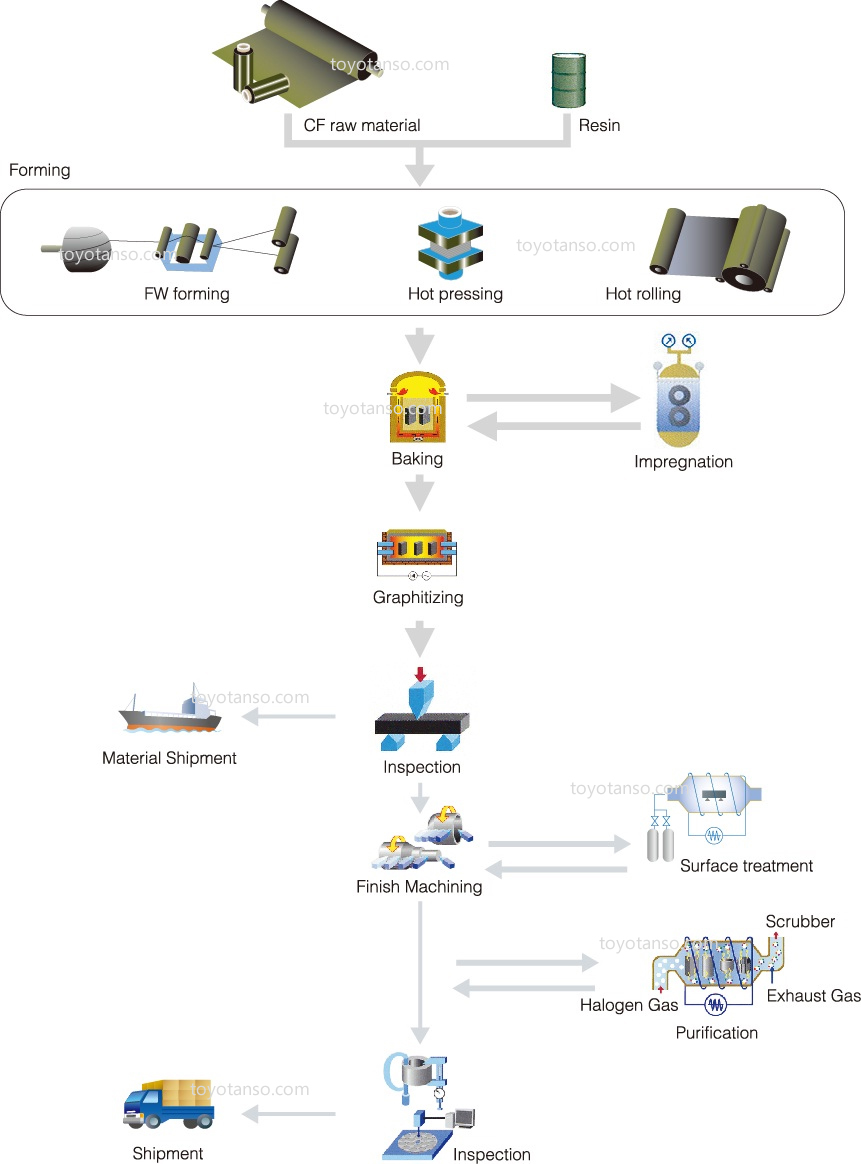

Manufacturing Process

Application

Toyo Tanso’s special graphite products are highly regarded for their excellent performance and reliability and are used across a wide range of fields that are essential in our everyday lives.

In the environmental and energy industry, our products are used for solar cell manufacturing, atomic power and aerospace applications.

In the electronics industry, we provide materials for various manufacturing process such as polycrystalline silicon and single crystal silicon, white LEDs, and high-frequency device.

Basic applications of our products include industrial furnaces, continuous casting dies such as those for copper alloys, optical fibers, and EDM electrodes for mold manufacture.

Electronics

For production of silicon monocrystals

Silicon wafers are the raw material used for IC chips.

The manufacturing process involves an extremely high melting temperature of 1,500℃. As wafer diameters continue to increase, C/C composites are gradually becoming a popular alternative to isotropic graphite because of their high heat resistance and lightweight construction.

・Products can be made with thinner walls, making it possible to pull up larger diameter crystals with smaller equipment.

・Designs can handle differences in thermal expansion during quartz crucible and silicon solidification processes by adjusting the fiber orientation.

General industrial furnaces

For heat treatment furnaces

For hot press furnaces

• Equipment can be kept smaller, helping to reduce installation costs.

• Sintered material sizes can be kept larger, helping to improve productivity.

• Heat capacity and energy costs can be reduced.

Toyo Tanso's C/C composites are now being used in aerospace applications that require durability in harsh environments and high-precision processing!

Our C/C composite is used in the ion engine that will be the propulsion power for Hayabusa2. It was a big challenge for us because many small holes had to be machined in the thin-walled disk, which required extremely high dimensional accuracy.

Environment and Energy

For production of silicon for solar cells

For nuclear energy plants

Automobiles, other means of transport, etc.

For sliding members