C/C composite

C/C composite is a carbon-carbon composite material reinforced by high strength carbon fiber, which has superior properties such as light weight, high mechanical strength, and high elasticity. Because of their unique features, our C/C composites (CX series) are used in a wide range of fields such as electronics, environment and energy, general industrial furnaces, and automobiles and other means of transport.

Property Data

Typical properties

| Shape | Material | Bulk Density (Mg/m3) |

Electrical Resistivity (μΩ・m) |

Flexural Strength (MPa) |

Flexural modulus (GPa) |

Tensile strenght (MPa) |

Coefficient of Thermal Expansion RT〜1273K(10-6/K) | Thermal Conductivity (W/(m・K)) |

C/C type | Description | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| - | - | - | - | - | (⊥) | (//) | (⊥) | (//) | ||||

| Flat plate | CX-741 | 1.51 | 23 | 140 | 46 | 185 | 8.1 | <1 | 6 | 35 | 2DC/C | Medium strength (Molding method A) |

| CX-761 | 1.58 | 20 | 185 | 55 | 250 | 8.4 | <1 | 9 | 44 | High strength (Molding method A) |

||

| CX-742 | 1.48 | 24 | 130 | 42 | 170 | 7.8 | <1 | 5 | 34 | Medium strength (Molding method B) |

||

| CX-762 | 1.58 | 21 | 170 | 50 | 185 | 8.2 | <1 | 8 | 42 | High strength (Molding method B) |

||

| CX-231 | 1.63 | 19 | 186 | 52 | 220 | 9.3 | <1 | 8 | 50 | Large diameter bolts, nut components, spring components |

||

| CX-31 | 1.61 | 22 | 90 | 23 | 98 | 4.1 | <1 | 12 | 52 | Nut and bolt components | ||

| C/C-201 1) | 1.50 | 30 | 147 | 47 | 127 | 8.2 | <1 | 5 | 20 | Medium strength, nut and bolt components |

||

| Profiles | CX-743 | 1.48 | 24 | 130 | - | - | 7.8 | <1 | 5 | 34 | Profiles | |

| CX-763 | 1.58 | 21 | 170 | - | - | 8.2 | <1 | 8 | 42 | Profiles with high strength | ||

| Cylinders | CX-45 | 1.44 | 24 | 105 | 34 | 114 | 8 | <1 | 4 | 34 | Medium strength cylinder | |

| CX-47 | 1.52 | 23 | 140 | 45 | 154 | 8 | <1 | 6 | 35 | High strength cylinder | ||

| Crucibles | CX-510V | 1.57 | 13 | 195 | - | 290 | 7 | <1 | 7 | - | FWC/C | FW crucibles |

| Cylinders | C/CFW 1) | 1.50 | 12 | 245 | - | 245 | - | <1 | 5 | 30 | FW hot press molds | |

| CX-55 | 1.60 | 11 | 195 | - | 290 | 7.4 | <1 | 7 | - | FW cylinders | ||

| Tiles | CX-2002U 2) | 1.65 | 2.7,3.4,5.1 (X,Y,Z) |

47,43,17 (X,Y,Z) |

- | 35,30,11 (X,Y,Z) |

5.3 (Z) |

1.7,2.3 (X,Y) |

190 (Z) |

390,320 (X,Y) |

felt C/C | Use in nuclear energy plants |

| Isotropic graphite(IG-56) |

1.77 | 12 | 43 | 10 | 27 | 4.7 | 104 | |||||

| Shape | Material | Bulk Density (Mg/m3) |

Electrical Resistivity (μΩ・m) |

Flexural Strength (MPa) |

Flexural modulus (GPa) |

Tensile strenght (MPa) |

Coefficient of Thermal Expansion RT〜1273K(10-6/K) | Thermal Conductivity (W/(m・K)) |

C/C type | Description | ||

* The figures above are typical values, and are not guaranteed.

1) Manufactured by Ohwada Carbon Industrial Co., Ltd.;

2) The direction of lamination of the felt is designated as the Z-axis and the directions within the plane as X- and Y-axes.

Available sizes

| Grade | Dimensions (mm) |

|---|---|

| CX-741,CX-761,CX-231 | 2000*1500*0.8 -30, 2000*500*100 |

| CX-742,CX-762 | 3000*1500*0.8 -30, 2000*500*100 |

| CX-31 | Max.850*400 3.2-90t |

| C/C-201 1) | 1020*970*1-12, 970*720*1-12 |

| CX-45.CX-47 | Inner diameter ø300-1400, 1400L |

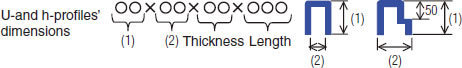

| CX-743.CX-763 |

U-profile 80*20-145*1.2*1000 h-profile 107*44*1.5*1000 |

| CX-510V |

Max.inner diameter ø1168(46" crucibles available) |

| C/C-FW | Max. ø950*800h, 20-150t |

| CX-55 | Inner diameter ø10-1400, 2000L |

| CX-2002U | 40*150*150 (X*Y*Z) |

※Please contact us for other sizes.

Product Inquiry

Inquiry form for C/C composite

Please wait a few seconds.

If the form does not appear after a few moments,Hereplease contact.

FAQ

- What is the difference between C/C composite products and CFRP?

- What temperature can C/C composite products be used?

- Can C/C composite products be used for heat treatment applications?

- Can C/C composite products be used in oil quench?

- Can C/C composite products be blasted?

- We currently use metal trays, baskets, and hearth rollers, what are the benefits of switching to C/C composite products?

- Is it possible to change only the work trays to C/C composite products?

- Is the C/C composite available in board or strip form?

- Does Toyo Tanso offer standard sizes for C/C composite springs? Can you manufacture custom sizes?

- Although the Grade CX-2002U is designed for nuclear power applications, is it also available for other applications?

- Does Toyo Tanso offer processing services for C/C composite?

- Is using a C/C composite effective in minimizing thermal deformation of jigs or components?

- Is a C/C composite available in tray or container shapes?

- Are there ways to reduce deterioration and dust generation in C/C composite?

- Please tell me about the track record of C/C composite products in industrial furnace applications.

- Please tell me about the track record of C/C composite products.

- What grades of C/C composite is available?

- What information is required to machine a product?

- Is impregnation treatment available for C/C composite?

- Does Toyo Tanso offer machining services to produce parts in custom shapes?

- What types of processing are available for C/C composite?

- Can composite be used with both gas-cooled and oil-cooled systems?

- We are considering automation of the heat treatment process; however, tray deformation is a concern. Which grade of C/C composite is the most suitable?

- Is it possible to purchase C/C composite bolts and nuts?

- What is the process of delivering design products?

YouTube Channel

YouTube Channel

Carbon product FAQ

Carbon product FAQ

Carbon ABC

Carbon ABC