- GlobalNetwork

-

- Global Site

- Americas

-

- United States

Occupational Health and Safety

Occupational Health and Safety Measures

We aim to create safer, better working environments not only for our employees, but for everyone involved

in the carbon business.

We are engaged in efforts to achieve workplace safety, nipping dangerous situations in the bud by

effectively utilizing near misses and risk assessments.

Toyo Tanso Environmental, Health, and Safety Policy

- 1.New Year zero accident initiatives and making known the health and safety plan for the current fiscal year

- 2.Promoting health maintenance

- 3.Thorough environmental, health, and safety training and increasing safety awareness

- 4.Thorough measures to reduce industrial waste

- 5.Preventing heat stroke by raising awareness of its dangers

- 6.Improving work environments

- 7.Year-end zero accident initiatives

- 8.Reviewing current fiscal year health and safety activities and planning activities for the next fiscal year

Targets

Toyo Tanso is aiming for zero accidents.

| 2024 Targets | 2024 Results | |

|---|---|---|

| Occupational accidents | 0 | 4 |

| Traffic accidents | 0 perpertrators | 16 perpertrators |

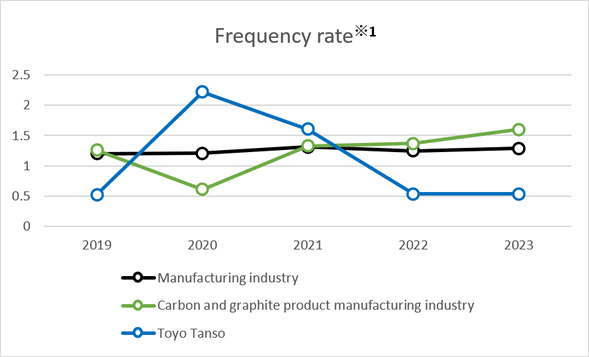

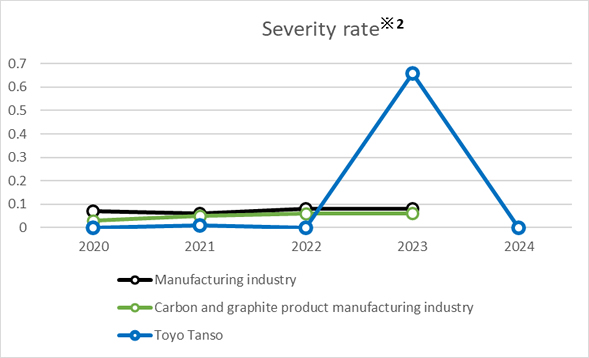

Occupational Accident Frequency and Severity Rates

※1 Number of occupational accidents and deaths per one million hours actually worked,

an indication of the occupational incidence rate.

No. of occupational accidents and deaths / No. of hours actually worked x 1,000,000

※2 Number of workdays lost per one thousand hours actually worked, an indication of

occupational incidence severity.

No. of workdays lost / No. of hours actually worked x 1,000

Environmental Health and Safety Committee Activities

At Toyo Tanso, employer, labor union, and employees participate in Environmental, Health and Safety Committee meetings held once a month at each site. The committee deliberates and shares information on health and safety activities, including efforts to prevent hazards to workers and prevent health problems, as well as measures to prevent the causes and recurrence of occupational accidents.

- 1.Accidents are prevented from recurring thanks to horizontal expansion of solutions developed using analysis of the causes behind emergencies and accidents.

- 2.Accidents are prevented by sharing reports on near misses with the entire company.

- 3.Thorough legal compliance is ensured by sharing revisions of laws and regulations.